-

Products & Services

-

-

News & Events

-

Packaging Capablility

100,000-level purification workshop intelligent packaging production line with customized solutions

Flexible Packaging Suitable for Various Applications

You can meet the requirements of the entire packaging process from a single point of contact: packing, labeling, box packaging and palletizing. Our product portfolio includes a wide range of modular solutions that can be configured together into compact, customized solutions.

We can provide small-batch and large-batch outer packaging lines suitable for various types of product specifications, including urine sleeve inner packaging materials and drug delivery devices. Focus on robot technology, rapid specification conversion and light processing to ensure high production reliability and efficiency.

Modular Layout for Customized Packaging Line

· Quick conversion of various specifications and repeatable settings

· Clear organization and user-friendly equipment operation

· Ergonomic design can optimize production and human-machine interface operation

· Various controls can be combined according to the application

· Serialization for traceability

· Can connect and assemble equipment to realize complete and immediate solution

Learn About Our Range of Solutions

· Coding and packaging

· Modular and multi-function secondary packaging production line with packaging and labeling units, all from one source

Our Strengths

Flexible production

Our modular solution can economically handle different product specifications. We meet your plan and provide a wide range of feeding and sorting systems for small batch packaging and high-speed production lines.

Fast specification conversion

Handling multiple product specifications or developing new combination products requires highly flexible packaging machines. Quickly convert or automatically convert different packaging specifications without tools

Complete solution

Engineers have developed a solution to realize assembly and packaging on the same production line by using internal comprehensive capabilities and our modular approach.

Success Cases

The key to our success is listening to your needs. At each stage, we will provide you with professional project management, flexible methods and firm commitment to provide the products you need. Learn more about our success stories.

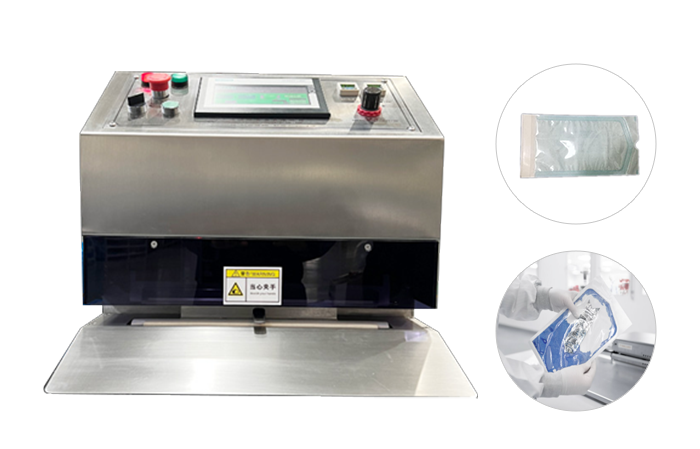

Soft sterilization bag sealing equipment

Sterile packaging and sealing machine

Advantages:

· Suitable for vacuum sealing of various sterilization bags

· Direct compression sealing ensures smoother, more reliable, and aesthetically pleasing welding

· Complies with CE safety standards, and the entire machine meets GMP requirements

· Digital management

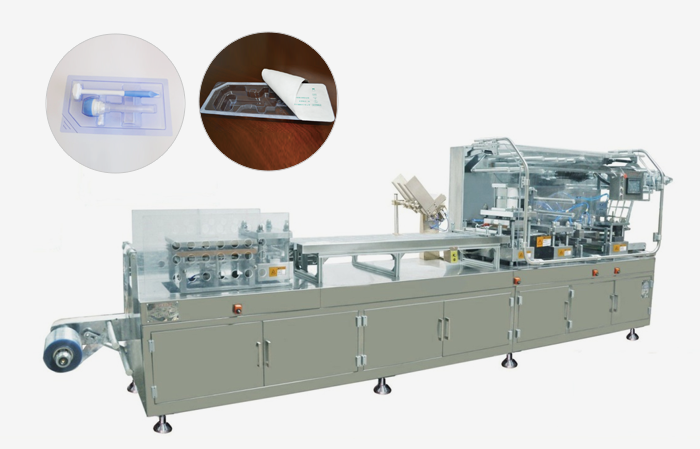

Soft blister packaging production line

FORM (bottom cutting forming) - FILL (automatic filling of packaging line) - SEAL (bag mouth sealing)

Advantages:

· Good moisture resistance;

· Excellent packaging printing effect and good display effect;

· Has excellent dustproof performance;

· The packaging bag material is recyclable, green and environmentally friendly;

· The production line is fully automatic and integrated, greatly saving manpower and increasing production capacity.

· The production process does not produce dust or impurities, and will not cause pollution to the product.

Hard blister production line

Good toughness and strength, with excellent chemical resistance

Advantages:

· Rapid forming speed

· Stable and reliable molding quality

· Sterilization applicability: irradiation sterilization, EO sterilization

Your One-stop Partner

Are you struggling to manage different vendors, different interfaces and incompatible technologies? DSB combines professional technology and solutions to obtain a simplified experience from one source. Learn how to leverage our comprehensive capabilities to support you.

If you have more needs?

Welcome your message, we will reply you in time.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

355 Longjin Road, Changzhou Economic Development Zone, Jiangsu Province, China