-

Products & Services

-

-

News & Events

-

DSB Steps

which specializes in R&D, manufacture and marketing ofdisposal medical products.

DSB Steps

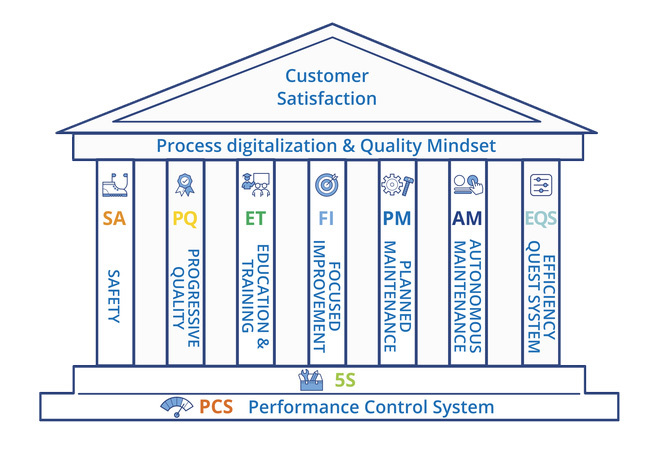

DSB STEPS is based on a management system based on DSB's business and industrial capacity, which aims to meet the needs of customers with the same quality level worldwide. It is a practical system implemented in accordance with relevant regulations.

DSB STEPS operates through structural collaboration, short -term and long -term ability assessment, providing operational insights and linked performance with the process plan.

This system helps us achieve high performance strategies and operating goals, continuously improved, promote integration, create and maintain development capabilities, satisfy and surpass customer expectations, and gain competitive advantages.

DSB Steps

The DSB STEPS plans are formulated in three stages, starting from the beginning of determining safety priority and creating a continuous improvement sharing plan-basic phase-to the safety culture-advanced stage of implementing safety standards and implementation of behavior-driven behavior.

In the end, the combination of safety with new products and process development.

DSB Steps

DSB STEPS is based on a management system based on DSB's business and industrial capacity, which aims to meet the needs of customers with the same quality level worldwide. It is a practical system implemented in accordance with relevant regulations.

Performance Control Systems

A set of KPIs for fast decision making, sustainable results and consistent quality in our products and services globally.

Shine, Standardize and Sustain

A methodology of workplace organization through the implementation, maintenance and improvement of separation, order and cleaning. It is the basis on which to build an effective system of managing the working environment.

Safety

Ensuring a safe working environment by developing the zero-incident system and promoting correct behaviors at all levels.

Focused Improvement

Contributing to the definition of the improvement strategy and developing the Factory Control System to ensure the continuous application of the achieved standard.

Efficiency Quest System

It involves corporate functions, providing the management with a structured method to share values and deliver results through their function.

Autonomous Maintenance

The aim is to increase production operators’ awareness and skills in basic maintenance tasks in order to deliver tangible and sustainable improvements in equipment reliability.

Planned Maintenance

Its goal is to minimize unplanned stops and anomalies with an impact on the final product. The Planned Maintenance strategy is based on the opportunistic planning of technical interventions and the integration with the Autonomous Maintenance pillar.

Education & Training

Ensuring the development of skills and organization in accordance with the Group’s continuous improvement strategy through the implementation of consistent and continuous training paths, a common evaluation system and periodical checks of training methods.

Progressive Quality

We accompany our customers through the life-cycle of their products, setting up a self-sustaining standardized system that delivers the highest possible quality, anticipating their needs and ensuring end-user safety.

If you have more needs?

Welcome your message, we will reply you in time.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

355 Longjin Road, Changzhou Economic Development Zone, Jiangsu Province, China