-

Products & Services

-

-

News & Events

-

Incontinence Healthcare

Inspiring a healthier life for everyone, everyday

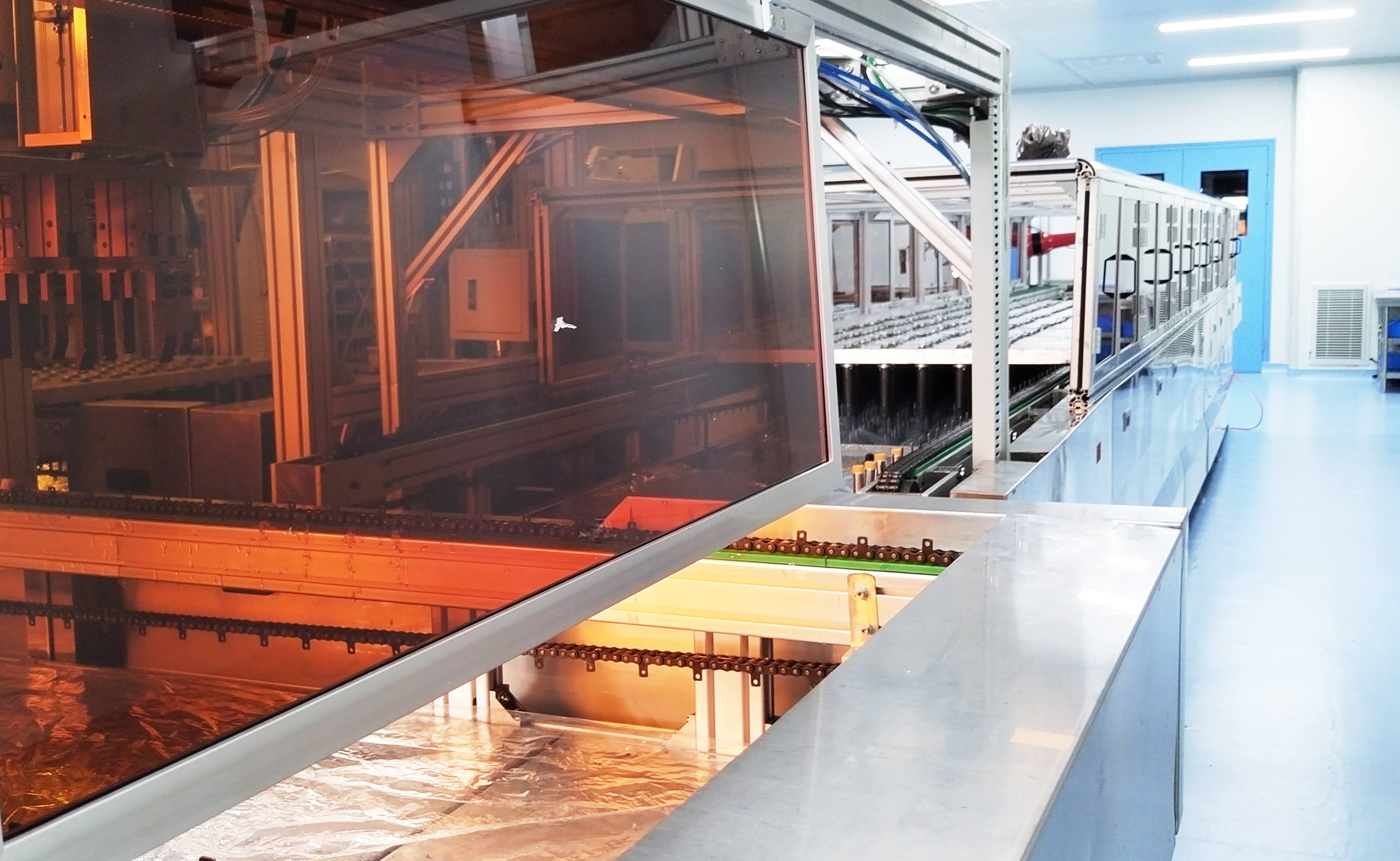

Automation Diping/Gluins Line

The equipment is easy to use to ensure high-speed production, reduce defective products, and produce products with the same appearance and size. Except for the replacement of raw materials and packaging materials, the entire automated production line requires the participation of personnel, and the rest of the process flows automatically to ensure that no one intervenes in the entire process to affect the final molding.

Advantage

1. Advanced technology, easy to use automatic production line, maximize production efficiency, prevent human errors, produce high-quality urine sets, and carry out automatic packaging.

2. Each process step can be adjusted according to customer needs, and can efficiently customize and produce products required by customers.

3. Through our rich experience in design solutions and dimension control technology, we are able to provide stable and mature processes to ensure highly reliable and safe key process steps for manufacturers.

4. All equipment can operate at high speed, and is equipped with an easy-to-use interface to ensure seamless high-speed production, reduce defective products, and make the urine sleeve meet the appearance and size standards.

Features

Parameters of urine sheath production line: output 2.5W/D (10h)

Number of urine tubes produced per cycle: 28

Optional specifications:18mm、20mm、25mm、29mm、32mm、36mm、41mm

Process Control

1. Gluing machine: high precision of gluing position and even gluing

2. Dipping depth: the depth of glue in the glue tank is controlled by the sensor

3. Bake glue: stabilize the temperature in the drying channel and oven through temperature sensor

4. Stripping: the position of the roll sleeve is accurate and convenient for the precise positioning of the stripper

5. Packaging: automatic blister packaging machine, which can pack each urine bag as required and automatically code

Tubing Extrusion Line

Professional production of various types of medical catheters, automatic tube pulling and cutting, with high production capacity and excellent quality

Medical soft polyvinyl chloride plastic in accordance with GB15593-1995

Urine Bag Production Line

Fully automatic production line

The machine adopts PLC control, with touch screen setting parameters, and automatically completes: film placement, shaping, bag body welding, traction film pulling, bag body cutting, and finished product stacking

Injection molding equipment

It has several high-precision injection molding equipment

Features

Capable of processing and producing various medical plastic parts

Advantages

High precision

High production capacity

Excellent quality

FFS Packing line

Full Name:

FORM(cut bottom forming)-FILL(automatic filling in packaging line)-SEAL(bag sealing)

Technical advantages:

1 Good moisture-proof performance;

2 Excellent packaging printing effect, good display effect;

3 with excellent dustproof performance;

4 The bag material can be recycled, green and environmental protection;

5 The production line is fully automatic and integrated, which greatly saves manpower and increases production capacity.

6 Production process does not produce dust, impurities, will not cause pollution to the product.

If you have more needs?

Welcome your message, we will reply you in time.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

355 Longjin Road, Changzhou Economic Development Zone, Jiangsu Province, China